Protect material, support maintenance, reduce effort, increase wind yield - initiated by the Bremen coordination office ForWind – Center for Wind Energy Research (Bremen, Hanover, Oldenburg) has started a research project at the University of Bremen that aims to enable the ecologically and economically optimal operation of wind turbines with the help of a digital twin. To this end, ForWind members, the Institute for Integrated Product Development (BIK) and the Institute for Electrical Drives, Power Electronics and Components (IALB) are developing a research wind turbine into a cyber-physical system.

The title of the three-year research project is "Concept and structure of a cyber-physical system for the holistic development of wind turbines" (WindIO). It has a total volume of 3.1 million euros and is funded by the Federal Ministry for Economic Affairs and Energy with almost 2.1 million euros in the 7th energy research program "Innovations for the energy transition". The project is supported by the project management agency Jülich.

In addition to the BIK and the IALB as research partners, five companies are involved as development and application partners: CONTACT software (Bremen), Pumacy Technologies (Berlin), fibretech composites (Bremen), German WindGuard (Varel) and SWMS Consulting (Oldenburg) as well as associated partners Wind Turbine Engineering (Bad Doberan) energy & meteo systems (Oldenburg) and German wind technology service (Ostenfeld).

The solution lies in the use of "digital twins"

The project partners are certain that if the technical possibilities offered by digitization were better used, wind turbines could be operated in a more environmentally friendly and economical way. In their research and development, they rely on the "digital twin". This is the virtual image of a real, i.e. physical system such as a wind turbine. In the WindIO project, the digital twin will map the dynamic model of the "Krogmann 15-50" research wind turbine of the IALB in Bremerhaven. A second research wind turbine from the University of Bremen is also used for WindIO research, a 3.4 megawatt system operated by project partner Deutsche WindGuard.

Prediction of operating behavior and service life

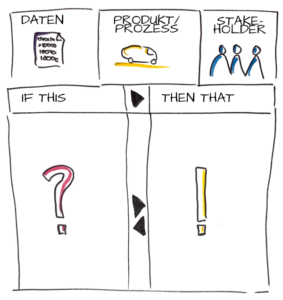

In order to be able to digitally map the real conditions in real time, operating data must be continuously recorded and fed into the digital twin. This requires a large amount of sensor data. If the mechanical and electrical components are connected to an information-processing system via a communication network, the system is referred to as a cyber-physical system (CPS). The digital twin is a special application of a CPS. It supports tests and forecasts - from production and logistics to wind turbine operation and the final recycling of wind turbines. The link with weather and load forecasts allows, for example, a prediction of the operating behavior and service life. The behavior of systems or their individual components in real operation can thus be better predicted.

Test with Bremen's 3.4-megawatt research wind turbine

The software architecture developed on the basis of the Krogmann wind turbine is to be used in parallel for a digital twin of the second research wind turbine. In this way, knowledge about the industrial transferability of the methodology to larger plants can be collected and statements about the broad effectiveness of the methodology can be made.

“So far, digital twins have not been used across the board in wind energy technology. One reason for this is the mostly restrictive information management in the wind industry. This delays the development of higher-level operating and optimization strategies, and the potential of digitization cannot be fully exploited,” says Dr.-Ing. Christian Zorn, head of the ForWind coordination center at the University of Bremen. One project goal is therefore particularly important to him: "With the WindIO twin, we want to establish a database that enables the exchange of system-specific information for different user groups."

Universal, freely accessible platform

The WindIO work is intended to create a transparent data basis and a freely accessible research platform for the development and integration of new ideas and optimization approaches. This opens up completely new possibilities for comprehensive research activities with real field data, which can serve as a basis for technical and economic simulations for business model development, among other things.

The WindIO system should make a significant contribution to improving the forecasts of maintenance and the load-minimum control of wind turbines. Continuous, real-time-capable adjustments to the current operating, load, and environmental conditions and consideration of the individual boundary conditions should guarantee optimal operational management, which contributes to a significant cost reduction in energy production and the best possible protection of resources.

Sabine Nollman