With the term internet of things the connection of systems, devices and everyday things to the Internet is described. In principle, the term does not differentiate between the exact type of connection and the resulting design of the application. Industrial Internet of Things (IIoT for short) is a collective term that describes the connection of industrial machines and production systems. The term Internet of Things on the other hand, is often used with an eye toward ubiquitous, consumer-facing IoT products.

IoT and IIoT - A technical difference?

If you look at the application examples for the Internet of Things that are already known today, then two large categories can be distinguished with regard to the user target group: On the one hand, the focus is on consumers and end users who use IoT-based applications. These are, for example, everyday systems such as smart household appliances, lighting and heating in smart homes that can be controlled via apps, services in cars or digital voice-based assistants. On the other hand, more and more machines in our industry are being networked via the Internet and are feeding our visions of digital factories in the so-called Industry 4.0 age. Here, the addition "Industrial" before the term "Internet of Things" often emphasizes a special application category (the so-called IIoT).

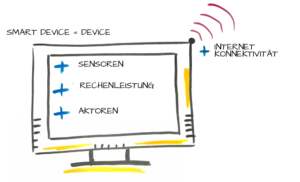

As we did in our Definition of the Internet of Things have described, there is no essential difference in the technical core of both application examples. The electrical control system under consideration, which is often mechanical, is given the additional ability to record environmental parameters using sensors. In addition, the actuators can be influenced. In both directions, applications on the Internet can gain knowledge from the recorded data and pass it on or transfer the decisions made to the actuators. From the point of view of the basic technical principle, there is initially no difference between a smart coffee machine in our consumer kitchen, which records the fill level of the beans and reorders, or an industrial coffee roaster at our coffee producer, which records and controls the temperature, degree of roasting and duration.

System integration vs. classic product development

The organizational framework conditions from which the innovation of an internet-enabled, networked system is to emerge differ much more than the actual technology. In the industrial context, the market was and is often characterized by so-called system integrators, who plan, assemble and ultimately commission appropriate solutions for their customers from machines, machine components or modular systems from the automation world. The classic control cabinet construction, a 24V-based low-voltage network for industrial sensors and actuators, as well as customer-specific programming in programmable logic controllers for this environment are often characteristic. In our opinion, the challenges for the IIoT do not lie in the technology itself. System integrators certainly have some catching up to do when it comes to dealing with Internet-based protocols and data connections, and the security issue cannot be dismissed out of hand either. Nevertheless, almost all providers of programmable logic controllers and also many providers of machine systems have long since integrated sufficient access options to the process images of the control programs. The mere reading of data in the sense of an initially continuous monitoring is therefore, contrary to what is often claimed, less complex and often not rocket science.

The applications afterwards, i.e. how you as a user of IIoT-based systems, for example with your networked production line, more quickly, more flexible and safer and yours increase sales or yours Costs significant reduce, will usually require more effort than technology.

The effort involved in developing IIoT solutions looks significantly different in classic product development. In many cases, the development teams have grown over the years in the development of electronic components, for example for existing products such as household appliances or cars. Compared to the often very individual production lines in an industrial context, these products are mass-produced and therefore have individual electrical circuits. Sometimes there are even industrial systems on the market that rely on their own electronic developments instead of programmable logic controllers. The technical hurdle of getting the systems connected to the Internet in the first step is sometimes more difficult, since in development projects the connection to the Internet, be it via Bluetooth, WLAN or wired, often has to be implemented in the form of additional hardware. The connection of the protocols, with which the data exchange of sensors and actuators with central IoT platforms is then to take place, also requires the adaptation of the software that is used on the microcontrollers. Due to the variety of approaches, the learning phase is usually not insignificant in order to network so-called embedded systems. The good news is that more and more components are available on the market that make the start and subsequent implementation much easier. This is partly because the applications and business models that result from connectivity can be successfully established for more and more companies and best practices can be copied.

Different tasks that IoT and IIoT should fulfill

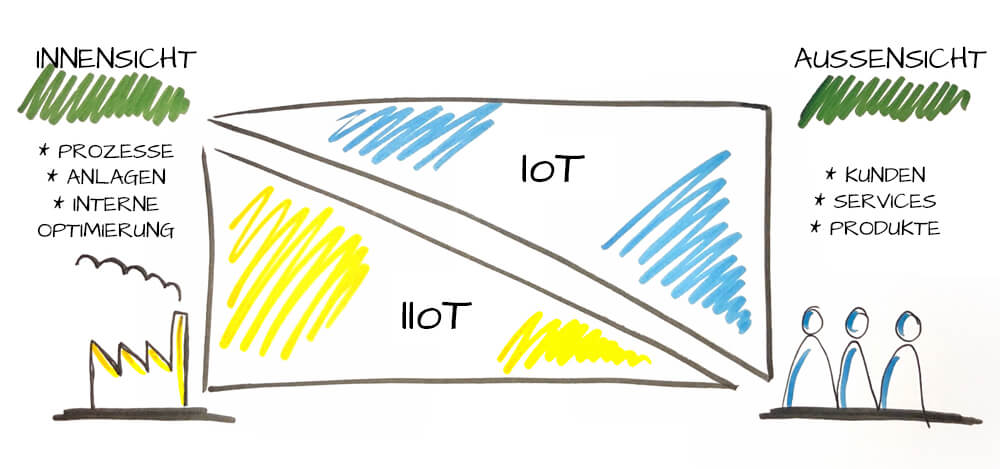

In addition to the organizational framework in which the solutions (should be) created, IoT and IIoT often have completely different tasks to fulfill. A hard definition is certainly not quite accurate, but the IIoT and Industry 4.0 projects are often very much inward-looking, towards your own company and your own processes. They are aimed at progressive automation and thus at a further increase in the efficiency of the processes. So it is not surprising that frequent use cases are preventative maintenance, the quality assurance or the post calculation of orders, ie the areas that often have a high need for information and which previously had to provide relatively complex and therefore expensive support processes in industrial production due to a lack of information.

If systems are delivered to customers who then continue to be operated to varying degrees, for example through maintenance contracts with the customer, remote monitoring has become almost indispensable in order to avoid having to constantly carry out expensive service calls on site. To a certain extent, this already includes aspects of product-oriented IoT systems.

Iot projects and systems are much more outward facing towards the customer. Services can be offered around a core product that, supported by the technical possibilities of connectivity, bundle the non-cash benefit of a device sale with that of the service: the washing machine orders detergent automatically and needs-based, the refrigerator automatically orders new milk, the food processor has integrated recipe books and the car offers the best routes to the best restaurants in town in its navigation system. The business models and the resulting income streams can change significantly through the technology in products - and not only in consumer-oriented business. However, they have a significantly different objective than inward-looking IoT projects and are much more difficult to assess in terms of their profitability. At the same time, of course, the chances of developing new unique selling points in the market or opening up completely new markets increase.

Common Challenges

Especially in the early planning phases in companies, it is worth analyzing the different characteristics of IoT and IIoT in detail and deriving from this what type of project it is. This is not necessarily the black and white distinction between IoT and IIoT, but the basic objective has an enormous influence on further steps and tasks that have to be considered in the context of a business decision. Therefore, make the following points clear to yourself:

- What is the basic IoT strategy? Do you focus inwards and/or outwards?

- When you focus outward, what kind of innovation do you intend to innovate? A product innovation for your customer? A service innovation? A process innovation for your customer?

- In the case of inward application: What efficiency gain do you want to achieve? What is the ROI like?

- In the case of the external application: how do you want to achieve sales and profit? How do you differentiate yourself in the market? What is the business plan? What do you have to invest?

- What technical basis do you have today? Do you use programmable logic controllers and can you use the IIoT innovations of the controller manufacturers? Do you have your own electronics that you need to make internet-enabled?

- How is your team set up, where is it from? System integrators have different thought patterns than electronics developers, but both probably have deficits in know-how on how IoT can be implemented in their respective environments.

- What applications do you need in order to achieve the business goals after the technical connection? Anticipate the if-then scenarios: "If I have the information on the operating cycles of the components on a machine, then I know for 90% which parts have to be replaced during maintenance due to wear."

In all planning steps, consciously break away from approaches of the past and focus on customer benefits, whether internal or external.

Conclusion

No customer wants to set up a complicated VPN connection in order to then control a lamp in a special tool with keyboard input. You've probably seen what "Alexa, turn on the light" does. Break through old patterns and concerns, especially in the planning phase, because the technology with which ideas can be implemented leanly and securely is developing rapidly. The IoT technology is therefore much less often the bottleneck in IoT projects than is often thought and what is not yet possible today will certainly soon be possible in view of the enormous technical progress. Here makes the distinction between IoT vs IIoT not much difference.

So our summary conclusion is: Don't dwell too long on the definition of IoT vs IIoT but take on the ideas and resulting tasks that lead to a long-term IoT strategy. Create the technical and organizational possibilities by connecting the components and by training your team and then work step by step on the realization of your goals, regardless of whether it is about saving costs or generating new sales, but do not mix everything arbitrarily. Take the technical challenges seriously, but don't let them become an obstacle. Basically, the possibilities are only limited by your creativity and imagination.